Supply Chain Machine Learning

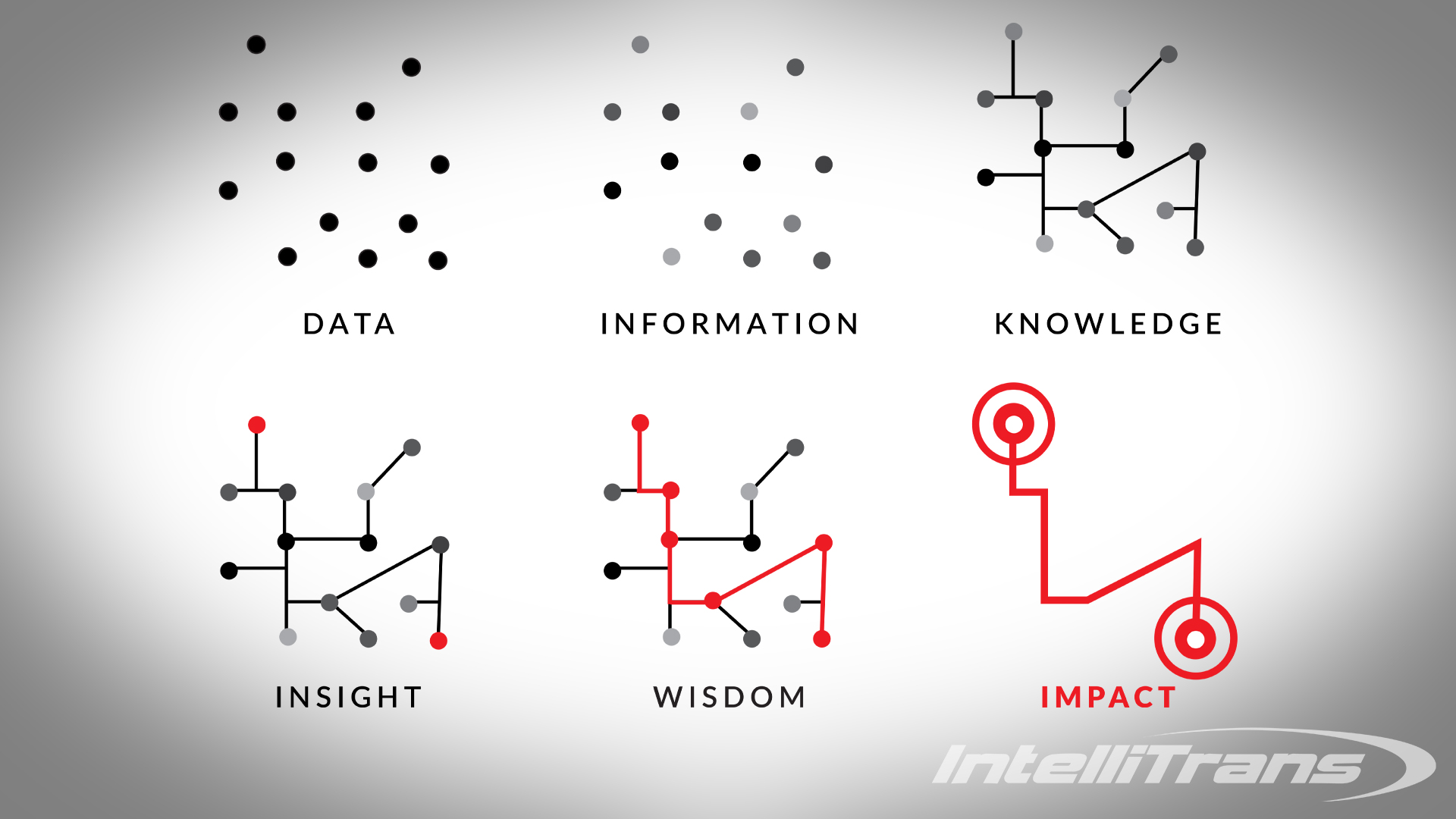

The IntelliTrans analytical toolkit has evolved over the years from Access databases, Excel spreadsheets, Crystal Reports, and OLAP Cubes to dynamic dashboards and scorecards. All these technologies, however, have focused on understanding past performance.

One of the most exciting developments in data analysis is the rise of predictive analytics and machine learning. Now that we understand what happened and why, we have moved towards predicting what will happen and how to optimize outcomes based on those predictions. The shift in analytical focus from past performance to future prediction is a disruptive force shaping many industries right now.

Using machine learning models, we’re able to provide our customers with better foresight to drive supply chain efficiencies and cost savings.

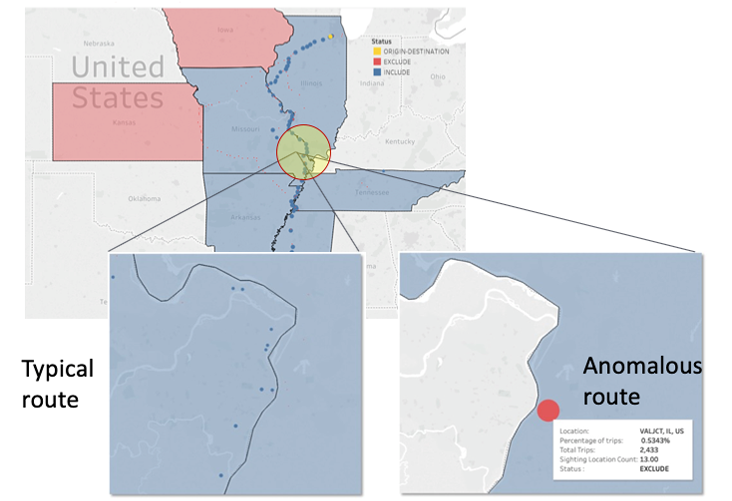

Early Shipment Out of Route Detection

Our machine learning models are based upon our 25 years of experience, and these models ensure the railroad handling error is caught and resolved as soon as the car displays anomalous behavior – usually before railroads themselves detect an issue. This early detection results in substantial savings, increased car utilization, and improved on-time delivery.

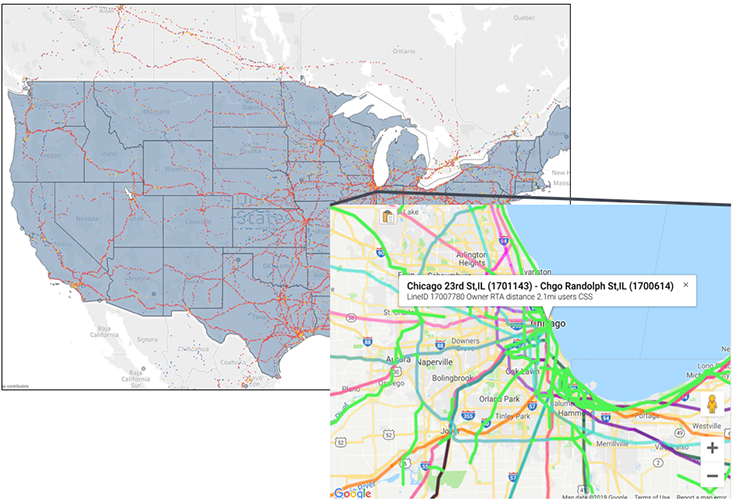

Shipment Exception Management & Prioritization

IntelliTrans also uses our machine learning models to predict trip plans for each trip. Any significant deviation from this predicted plan is flagged for resolution by our operations team with the carrier, which ensures these shipments receive timely attention and resolution.

Dynamic ETAs

We provide dynamic ETAs using machine learning models based on numerous factors, including but not limited to weather, network congestion, and switch schedules. This functionality provides a high degree of confidence around empty car supply, on-time delivery and complete transparency of the predicted whereabouts of every rail car, allowing shippers to remove ‘padding’ from fleet sizes and delivery times.

Fleet Sizing

We help customers optimize fleet size by simulating thousands of what-if scenarios based on probabilistic models. Proper fleet sizing minimizes cost and gives peace of mind that railcar supply is adequate to best serve the market.

Predictive Freight Cost Modeling

We provide accurate freight cost estimates for future shipments by utilizing machine learning models built upon our voluminous shipment and rate data. This enables our customer’s commercial teams to provide reliable quotes to their customers and our customers the ability to create accurate spend reports based on forecasted demand.

Bad Order Repair Duration

We help customers predict the duration of a bad order repair and incorporate that into our dynamic ETA so there is full ETA visibility of every railcar.